Hello everyone,

I work on various woodworking projects, such as outdoor kitchens and garden furniture. Currently, I’m using a Holzzman miter saw, but it’s not precise enough. I’m planning to build a workbench with a fence and saw stops and am looking for a new saw that will work well with this setup.

I’m torn between a radial arm saw and a miter saw:

For the miter saw, I’ve looked at the Bosch GCM 12 GDL Professional and the Makita LS1219L.

For the radial arm saw, I’m considering a second-hand model from DeWalt.

I don’t need to cut angles very often, but occasionally I need to make very sharp angles. I also want to know if a radial arm saw is useful for making joints by tilting the saw or for crosscutting.

My questions are:

- Is a radial arm saw precise and easy to work with?

- Which of the two works better with a fence for saw stops?

- Is a radial arm saw safe to use?

- Is it optimal for making joints or cutting in length with a radial arm saw?

- What is better?

- Do you have any other recommendations for a saw that works on 220/230V?

If you have better suggestions they are also welcome!

Thanks in advance for your help!

3 réponses

Thank you all for the very detailed, valuable and fast responses. I really appreciate it!! I am a young woodworker (20) and sell various projects in my spare time. I am considering turning my hobby into a full-fledged business after or even during my studies. I was born and live in the Netherlands  , but I am currently spending 6 months in Canada for an internship at a company that builds log cabins. I have only been on this platform for a week and I am already impressed by the helpful community here!!

, but I am currently spending 6 months in Canada for an internship at a company that builds log cabins. I have only been on this platform for a week and I am already impressed by the helpful community here!!

About my original question: I want to convert the saw into a long, fixed workbench with a guide and a length stop. How does this work then in combination with the guide of a radial arm saw?

(the radial arm saw is 220/230 volts, second hand)

Hello;

A miter saw will be less heavy, with finer blades and lower diameter (therefore less possibility of vibration). Negative toothing blades are possible to limit bursts. But it will be limited, due to its power and its decline to the most fable sections of wood. In return, it will make more thin and more precise cuts.

A radial saw like Dewalt in photo, will be more powerful, but often (always ?) In 380V. They are heavier, and more difficult to maneuver and settle. These saws are generally designed to cut sets or strong solid wood sections. (In French: TRONCONNER = crossing across, perpendicular to the wood wire. As opposed to DELIGNER = cut in length, in the direction of the wood wire).

In some cases, it is a means of making cuts on large widths (for the manufacture of stairs, for example).

They can be adjusted in orientation, as in inclination. Or length cuts with guide and stop.

But for all these operations, it will be less precise than a tab saw.

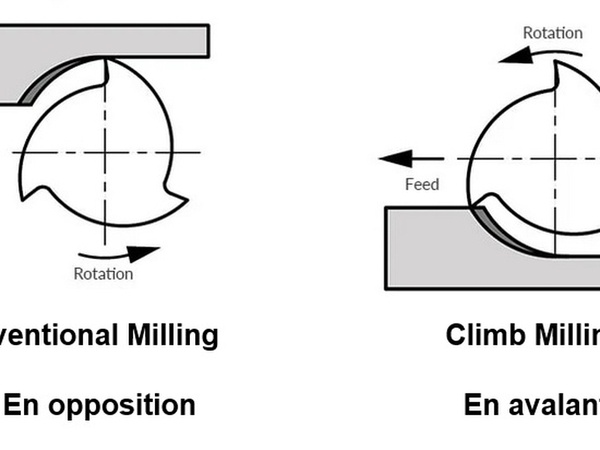

Regarding safety, the miter saw are equipped with fairly effective protectors. You must be maneuvering by backing up the blade in the high position, then lowering it and advancing towards the guide (EN OPPOSITION, in French).

On the other hand, a radial saw will cut by backing up in wood (EN AVALANT, in French), often of high section of wood. Specific blades are therefore necessary to limit the risk of kick back, but they remain more dangerous than miter saws.

The cutting of wood in the direction of the wire is possible, but must only be made in opposition, in this case. But it must remain a troubleshooting solution, and punctual, because it is clearly not the safest solution.

Hoping to have helped you a little, knowing that my English for the technical terms in very low ... and for the rest, just correct.

EDIT. Without being sure, I found this

1 :

Radial arms can be more precise than miters (less joints, surdier rails...) but requires more laborious setting up. It's not as fast as a miter when you want to change angles very often, but more precise when doing multiple identical pieces.

2 :

BUilding a workbench for a miter is a pain in the a** : several levels, right orientation and tight fixation of the tool... and if you change your saw, you must change the bench.

With a radial arm you just have to take a piece of plywood, make a cut to get a reference and place your fence... easy !

3 : any tool is as safe as you make it. As long as you use it for cross cutting with the right blade (negative rake saw blade) and with push sticks and clamps when required you're good.

4 : rip cutting is possible with a radial arm, but it becomes potentially dangerous : there's no ripping knife, the cut is not supported (the blade wants to pull the wood upward), setting the width is not easy...

For making joints, once you're set it's more precise than a miter...

5 :

Radial arm saw is more precise, can cut wider boards, and can do things you can't do with a miter ; it will probably last a lifetime. But it is not as easy to set and needs a huge space.

Miter saw is lighter, easy to use and fast to set, takes less space in the shop. But it's not very precise ; and probably won't last very long.

Thank you all for the very detailed, valuable and fast responses. I really appreciate it!! I am a young woodworker (20) and sell various projects in my spare time. I am considering turning my hobby into a full-fledged business after or even during my studies. I was born and live in the Netherlands , but I am currently spending 6 months in Canada for an internship at a company that builds log cabins. I have only been on this platform for a week and I am already impressed by the helpful community here!!

, but I am currently spending 6 months in Canada for an internship at a company that builds log cabins. I have only been on this platform for a week and I am already impressed by the helpful community here!!

About my original question: I want to convert the saw into a long, fixed workbench with a guide and a length stop. How does this work then in combination with the guide of a radial arm saw?

(the radial arm saw is 220/230 volts, second hand)